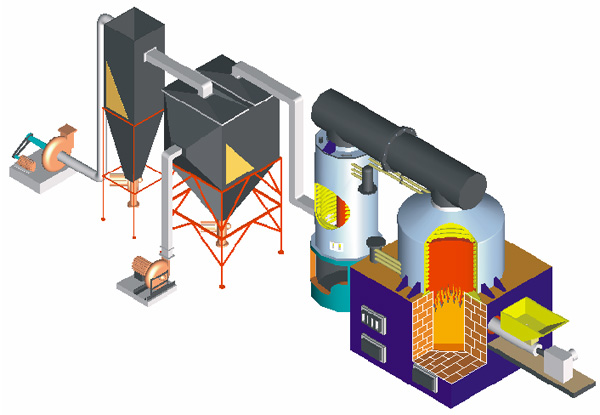

Thermic Fluid Heater – Efficient and Reliable Heating Solution for Industrial Applications

Thermic fluid heaters are a type of industrial heating equipment that use a special type of fluid as a heat transfer medium. They are designed to provide reliable, efficient, and safe heating for a variety of industrial applications, including chemical, pharmaceutical, textile, and food processing industries.

At MITTAL BOILERS, we offer a wide range of thermic fluid heaters to meet the diverse heating needs of our customers. Our heaters are designed to provide precise temperature control, high thermal efficiency, and low emissions, making them an ideal choice for industrial heating applications.

Benefits of Thermic Fluid Heater

- Efficient heating: Thermic fluid heaters provide efficient heating by using a special type of fluid as a heat transfer medium, which has a high heat transfer coefficient and low viscosity.

- Precise temperature control: Our thermic fluid heaters are designed to provide precise temperature control, ensuring consistent heating and minimizing the risk of overheating or underheating.

- Low maintenance requirements: Thermic fluid heaters have low maintenance requirements and are designed for easy cleaning and servicing.

- Low emissions: Our heaters are designed to minimize emissions, ensuring compliance with environmental regulations and improving the sustainability of your operations.

Thermic Fluid Heater Applications

Thermic fluid heaters are suitable for a wide range of industrial heating applications, including:

- Chemical and petrochemical industries

- Textile and garment industries

- Food processing industries

- Pharmaceutical industries

- Plywood and laminates industries

- Paint and coatings industries

Thermic Fluid Heater Types

We offer a wide range of thermic fluid heaters, including:

- Vertical Thermic Fluid Heater

- Horizontal Thermic Fluid Heater

- Solid Fuel Fired Thermic Fluid Heater

- Oil/Gas Fired Thermic Fluid Heater

- Electric Thermic Fluid Heater

Contact us today to learn more about our thermic fluid heater solutions and how they can benefit your business. Our team of experts will be happy to answer any questions you may have and provide you with a customized heating solution that meets your specific needs and requirements.